COLD GALVANIZING PAINT

Strongly concentrated out of zinc particles, GALVA ZINC MATT 97% helps to sustainably prevent corrosion on bare or galvanized steel surfaces, by forming an ultra-resistant self-protecting primer layer, ideal for the treatment of pipes, pipelines and pipelines, etc. GALVA ZINC MATT 97% has very good electrical conductivity allowing spot welding operations.

PROPERTIES OF GALVA ZINC MATT 97%

- Very good adhesion providing excellent support for paint

- Chemical resistant

- Long-lasting electrochemical protection

- Heat resistance : up to 350°C

- Dust-free drying : after 10 to 15 minutes

- Touch dry : after 20 to 30 minutes

- Recoverable after 24 hours (indicative values depending on temperature, coated thickness, humidity)

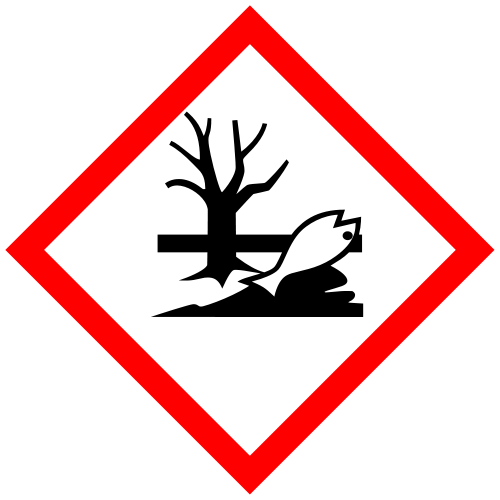

3 pictograms

CARASTERISTICS OF COLD GALVANIZING PAINT

1 COLOR

|

Cold Galva Paint - Zinc Matt 97% Metal finish |

COMPOSITION

Binder : epoxy-ester

Pigments : high purity zinc

Propellant gas : Dimethyl ether

PRECAUTIONS FOR USE OF GALVA ZINC MATT 97% SPRAY PAINT

- Shake well before use

- Remove paitn and rust residues with a wire brush or a sander

- Surface must be clean, dry and free of grease

- When usin outdours, remove any moss or algae deposits

- Cover surrounding areas

- Spray from a distance of 25 cm from the surface

- Apply several thin layers

- Between the various layers, respect a time of drying of approximately 20mn

HEALTH AND SAFETY

CLP labelling with three pictograms

Dangerous. Follow the precautions.

ACETONE

N-BUTYL ACETATE

SOLVANT NAPHTA AROMATIQUE LEGER (PETROLE)

H222 Extremely flammable aerosol.

H229 Pressurised container: May burst if heated.

H319 Causes serious eye irritation.

H336 May cause drowsiness or dizziness.

H410 Very toxic to aquatic life with long lasting effects.